Zero Breakthrough! Tronway's Single Wafer Wet Etching/Cleaning Tool Successfully Listed in the 2023 First (Set of) Major Technical Equipment (Suzhou, Wuxi and Changzhou)

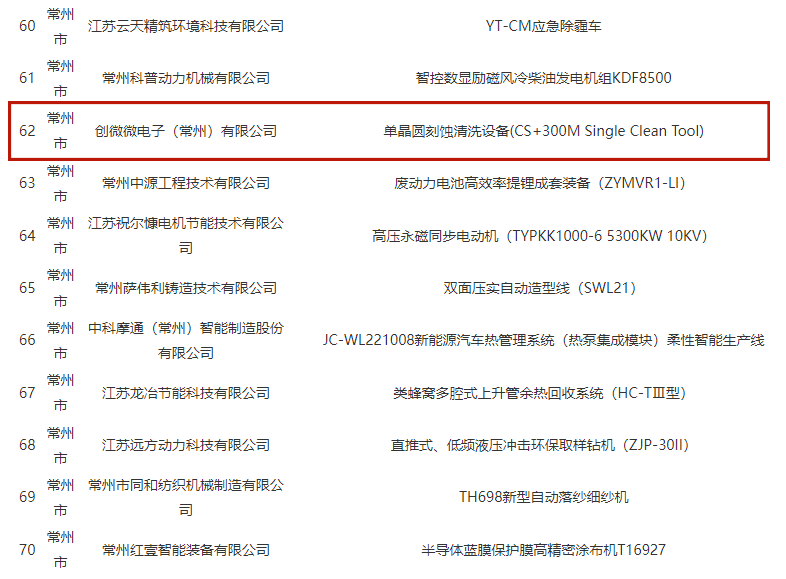

Recently, the Suzhou, Wuxi, Changzhou Bureaus of Industry and Information Technology jointly released the Proposed List of the First Set of Major Technical Equipment in Suzhou, Wuxi and Changzhou in 2023. The Single Wafer Wet Etching/Cleaning Tool developed by Tronway Changzhou Co., Ltd. was successfully certified for inclusion, committing a breakthrough from zero to one.

The purpose of certifying the First Set of Major Technical Equipment in Suzhou, Wuxi and Changzhou is to encourage and guide equipment manufacturing enterprises in technological innovation. The enterprises are encouraged to proactively research and develop high-end equipment and key components with independent intellectual property rights that achieve significant breakthroughs in overall performance or core technical specifications and reach a domestically leading or internationally advanced level. The certification is not only a recognition of the enterprises' technological strength and innovation ability, but also an affirmation of the enterprises' contribution to promoting the high-quality development of the manufacturing industry.

Established in 1997, Tronway Changzhou Co., Ltd., a wholly-owned subsidiary of Changzhou S.C Exact Equipment Co., Ltd., is a semiconductor equipment manufacturer utilizing state-of-the-art technology. The company is engaged in the R&D, design, manufacture, and sale of its portfolio of process equipment, which is mainly used for wet processes, including Photoresist Removal, Oxide Etching, Metal Etching, SiNx Etching, Pre-Tube Cleaning, etc.

The primary use of this qualified Single Wafer Wet Etching/Cleaning Tool is to remove residue from the surface of the wafers through a cleaning process. To clean the wafers, the residue is dissolved in the cleaning solution, then each wafer is rotated, creating a centrifugal force that directs the solution containing the residue off the surface of the wafer. Securing several independent intellectual property rights (including process chambers with linked "cups", ingenious "cup" elevation mechanism, multi-chemical & multi-function process handling lift, exclusive dosing method, and gas-liquid separation structure, etc.), this tool has won the intention to cooperate with several well-known enterprises.

The First Set of Major Technical Equipment certification is an effective factor in promoting the high-end, smart and green development of the manufacturing industry. In the future, Changzhou S.C Exact Equipment Co., Ltd. will facilitate the development process of Major Technical Equipment, further improve the R&D and application of the First Set of Major Technical Equipment, and look forward to making continuous contributions to the high-quality development of the equipment manufacturing industry.